Raisin Processing & Technology

At Mayboli Agrocare Pvt. Ltd., we are redefining raisin production with advanced, hygienic, and automated systems that ensure consistent quality, extended shelf life, and global market readiness.

1. Sourcing High-Quality Grapes

We work directly with trusted local farmers in Solapur to procure premium seedless grapes, especially the Thompson Seedless variety.

2. Drying Process

Green Raisins: Air-dried naturally to retain the green color and nutrients.

Golden Raisins: Treated with sulfur dioxide and air-dried under controlled conditions for a rich golden hue.

Black Raisins: Sun or mechanically dried to achieve a dark, rich texture and flavor.

3. Cleaning & Washing

Grapes are cleaned using high-pressure water jets and mild food-safe agents to remove impurities, pesticides, and residues.

4. Drying & Moisture Control

Moisture levels are carefully brought down from 75% to below 15%, ensuring shelf stability and preventing microbial growth.

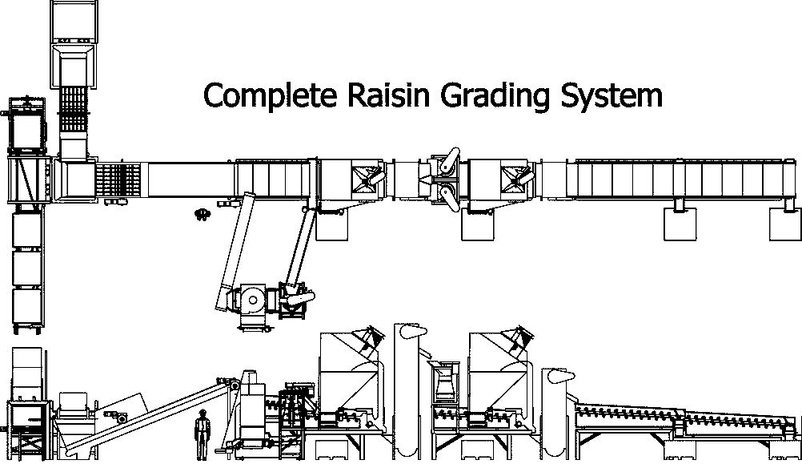

5. Sorting & Grading

After drying, raisins are sorted by size, color, and quality using automated sortex machines that eliminate inconsistencies.

6. Packaging

The raisins are packed in food-grade materials in various sizes for domestic and export markets, maintaining freshness and hygiene.